Our Capabilities

We are a team of creatives.

We expertise in manufacturing of precision milled and turned components and assemblies of any magnitude

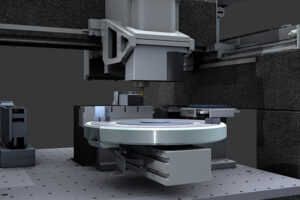

01. Precision Machining – For all material grades

02. Aerospace – Development & Tooling

03. Sub-assemblies and customize Gauges

04. Engineering services

05. Design and Development

06. FMEA(Design & Process FMEAs)

07. Documentation support for International Standards

Manufacturing

Using the power of digital to bring you to the next level.

Spike Aerotek Pvt Ltd has its key strength and is known for its proficiency in manufacturing.

Over the years we have gained recognition for manufacturing extremely complex 3D contoured components for a variety of industries.

We are exposed to a wide range of industries which gives us exposure to a large number of techniques and process from multiple market disciplines and we have successfully applied these techniques and proved our caliber on various occasions.

Every project is given equal importance and every stage in manufacturing is keenly observed and studied in order to bring out outstanding finish and conform to tight tolerances required by

No aspect of a design is overlooked and components are inspected at every stage to avoid human errors.

With the addition of advanced Turn-mill machines and much more refined 3 axis CNC machines, our ability to bring out components at the fastest rate with close tolerances and outstanding surface finishes has taken our skills to the next level.

We turn

design into art

Here at Spike Aerotek Pvt Ltd, our team focuses on achieving flawless designs and make products of high Quality.

Our design team uses latest software tools for modelling parts and assemblies of any propotion.

We have carried out ground up designs, design modifications of 3D contoured moulds and dies for plastic injection industries, rubber moulding industries, battery manufacturing industries, vacuum packaging industry etc.

What we

can do for you?

” Reverse Engineering !

Advance and bleeding edge technology is always adapted at Spike Aerotek Pvt Ltd.

We make use of modern techniques like 3D scanning and sophisticated tools like electronic height gauges and advanced software and skills to reverse engineer tools, moulds and dies.

Our mastery of these tools and techniques has provided us with the ability to design, manufacture, supply and get our products approved by our customers especially OEMs.

Quality

“Eventually everything connects – people, ideas, objects. The quality of the connections is the key to quality per se.”

- All components entering the facility undergo rigorous quality checks, be it raw materials or components in manufacturing stages or finished goods.

- We follow a 100% check policy for all manufactured components including those which came under large scale production.

- We provide customers with access to all levels of information and as many number of stages of inspections as demanded, to ensure that high quality standards are always conformed to at our facility.

- We maintain records of incoming quality reports, outgoing quality reports and material test reports for all components and is available to the customer when desired.

Quality is given the utmost importance at Spike Aerotek Pvt.

We follow the below mentioned procedures of quality check in order to maintain continuous output of high quality components.

A pre-production inspection: Raw materials, tools and machines are thoroughly inspected before the start of production so as to maintain deliverability of

A during production inspection: Every stage of manufacturing starts and ends with inspection so as to maintain high quality of products and make sure that problems are identified at early stages avoiding wastage of

Final Inspection: Manual inspection precedes all activities. Each component is measured and tested so that in a production batch, 100% of the products are inspected and adhere.

Quality Policy

“We the SPIKE AEROTEK PVT LTD team is strongly committed and dedicated to achieve total customer satisfaction by supplying precision machined component, Mould tool & Fixture with consistent quality product on time.

This achieved through total involvement of employees and complying with quality management system requirements and continual improving is effectiveness”